Bin turner for forklift: discover the Goubard range

Home > Forklift box turner

Forklift box turner

FILTER

FILTER

CUSTOM

MANUFACTURING

With a recognized know-how, an ability to listen and an expertise by trade, we enrich our wide standard range with customized products to become your ideal partner and offer you:

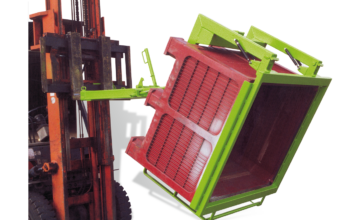

Forklift bin turner by Goubard

Do you need a device to quickly and safely empty your crates and pallets? Do you have stackers among your equipment? A Goubard forklift box turner is undoubtedly the most rational choice. Discover our range, including our mobile pallet tilters, to optimize your unloading operations, regardless of your industry.

Why get a forklift bin turner?

A bin turner is an essential piece of equipment in many industries. It allows you to easily handle and turn boxes, pallets, pallet boxes (palox), mesh boxes, etc. Such an equipment facilitates the optimization of these operations, as well as the handling and logistics processes in your company.

Superior efficiency

Using a forklift crate turner significantly reduces the time required for turning boxes and pallets. Automating this flipping process increases productivity by streamlining workflows, allowing employees to focus on higher-value tasks.

Enhanced security

Automating the rotation process with box turning devices reduces the risk of workplace accidents. Manual handling of heavy and bulky boxes can cause injuries. A forklift box tilter minimizes these risks, creating a safer and more ergonomic working environment.

Product protection

Mechanical turning of boxes and pallets ensures gentle handling of containers, minimizing the risk of damage.

Crate turner and mobile pallet tilter: for which industries?

Forklift box returns are used in many industries, including:

- Agri-food: for flipping boxes of potatoes, fruits, vegetables and other food products

- Pharmaceutical and chemistry industries: to handle boxes containing tablets or raw supplies

- Automotive industry: for turning pallets of spare parts and components

- Logistics and distribution: To facilitate the sorting and storage of goods in warehouses

- Agriculture: for tipping crates and pallets containing animal feed, foodstuffs, etc.

Our forklift bin turners and pallet rotators

Here are our best sellers in the category of forklift box turners and pallet tilters. And if you can’t find the right product, we can custom create your stacker handling skip.

Bottom Grip Box Turner

Our bottom grip bin turner is designed to provide efficient and secure case handling. Frame closing and tilting are manually controlled by a lever, facilitating simple and intuitive use. End-of-stroke cushioning is provided by springs, guaranteeing a smooth stop for operator safety and protection of the body.

The sliders have an internal section of 170 x 70 mm with a center distance of 375 mm, which allows it to be used with a wide range of forklifts. To enhance safety, a lock is integrated to a fork heel.

Frontal emptying is carried out by manually activated tilting, and the body is held firmly in a mobile frame, assisted by 4 gas springs. The tilt angle of this bottom grip bin turner reaches 145° to facilitate complete and efficient emptying.

Top Grip Box Turner For Forklifts

Our top grip bin rotator is custom made based on your specifications. It is available in several variations:

- Manual crate flipper: Designed for an admissible load greater than 500 kg. The box is held in a movable frame, assisted by four gas springs. Frame closing and tilting are manually activated by a lever.

- Semi-hydraulic forklift box tilter: Supports a permissible load of 1,000 kg. It works like the manual version regarding the movable frame. However, the tilting is activated hydraulically by two double-acting springs, to be connected to the forklift

- Fully hydraulic box turner: With upper frame and fully hydraulic tilting, to be connected to the forklift. As with the other versions, this attachment is custom made

Mobile pallet turner

Our patented pallet tilter (BPP05000) allows effortless emptying of pallet contents (bales of cardboard, plastic, bags, bulky items). This stacker equipment ensures complete emptying at a 56° angle.

This model accepts standardized pallets measuring 80 x 120 cm with a maximum load of 500 kg. It handles a maximum load length of 1100 mm, leaving clearance for claws on a 1200 mm pallet. The tilting is manually triggered by a lever, providing simple and intuitive use.

The Goubard forklift pallet tilter features sleeves for handling the forks, with an internal section of 145 x 55 mm and a center distance of 388 mm. For safety and precision, it includes two end-of-travel limiter cables and retaining claws during emptying.

How to choose your forklift box inverter?

The choice of a box turner must be based on several criteria which vary depending on the use of the equipment:

- Load capacity: check the maximum load capacity to ensure it can handle your crates (potatoes, wood shavings, etc.) and pallets

- Crate or pallet type: make sure the forklift turner is compatible with the specific type of crates, pallets or boxes you are using

- Compatibility with the forklift: The attachment must be compatible with the forklift in terms of dimensions and method of attachment

- Safety Options: Look for turners equipped with safety features like safety locks, ergonomic controls, etc.

Goubard: French specialist in forklift handling equipment

Goubard is a leader in manufacturing and distributing stacker equipment such as skips and attachments for forklifts. With decades of experience, Goubard offers robust and reliable French-made attachments.

Whether you’re in the food, logistics, automotive, or pharmaceutical industries, a box, pallet, mesh box, or pallet box turner can transform your handling operations. Trust Goubard for your forklift box rotators and mobile pallet tippers.

LOGIN